What are the differences between type A B C and D FIBC Bags

Bulk

Bags are classified according to one of four Types: A, B, C and D.

Type A Bags

Type A FIBCs are made of plain-woven polypropylene and other non-conductive fabrics. Static electricity is generated as products move over or rub against the inside surface of the bulk bag when they are filled/emptied. There is no static protection provided by Type A FIBCs

Type A bulk bags can be used to safely transport

non-flammable products. There should not be any flammable solvents or gases

present around a Type A FIBC.

Safe

use for type A FIBC Bags:

- To transport non-flammable products.

- No flammable solvents or gases present around the bag.

Do not use type A FIBC Bags for:

- Transporting flammable products.

- When flammable solvents or gases are present around the

bag.

Type B Bags

Type B FIBCs are similar to Type A bulk bags in that they are made of plain-woven polypropylene fabrics or other non-conductive material. Also like Type A bulk bags, Type B FIBC bags do not have any mechanism for dissipating static electricity.

The difference between Type A & B FIBCs is Type B are made from materials that have a low breakdown voltage to prevent an incident where highly energetic, and dangerous propagating brush discharges occur. Although Type B bulk bags can prevent propagating brush discharges, they are not considered anti-static bulk bags because they do not dispel an electrostatic charge.

Safe use for type B FIBC Bags:

- To transport dry, flammable powders.

- No flammable solvents or gases present around the bulk bag.

Do

not use type B FIBC Bags for:

- When flammable solvents or gases are present around the

bulk bag.

Type C Bags

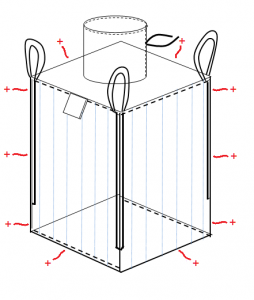

Type

C FIBCs, also known as conductive FIBCs or ground-able FIBCs, are

made from non-conductive polypropylene fabrics interwoven with conducting

threads traditionally sewn in a grid pattern. These conducting threads must be

electrically interconnected as well as connected to a designated ground/earth

during filling and discharging. This connection to the ground/earth during

filling and discharging is imperative to the safe use of Type C bulk bags.

Safe use for type C FIBC Bags:

- To transport flammable powders.

- When flammable vapors/solvents, gases, or combustable dusts are present in the bag.

Do

not use type C FIBC Bags:

- When ground

connection is not present or has become damaged.

- Resistance from

any location FIBC to ground-able point.

Type D Bags

Type D FIBCs are made from antistatic and static dissipative fabrics designed to safely prevent the occurrence of incendiary sparks, brush discharges and propagating brush discharges without the need for a connection from the FIBC to a designated ground/earth.

Type D FIBCs can be used to safely package combustible

products and handle products in combustible and flammable environments.

Safe

use for type D FIBC Bags:

- To transport flammable powders.

- When flammable vapors, gases, or combustable dusts are present.

Do

not use type D bulk bags:

- When surface of FIBC is contaminated or coated with conductive material such as water, grease or other flammable and or combustible materials.

0 Comments